I made a belt holster for my EDC multitool.

The Leatherman Crunch

The Leatherman Crunch is my dream multitool.

It’s the last tool designed by founder Tim Leatherman and what a banger it is. A folding pair of vise grips? As someone who often finds themselves tearing apart plastics and thin sheet metal, I need that ability to progressively chomp down on parts and wrench them apart. The Crunch is an absolute beaut piece of engineering: a competent pair of locking pliers with an adequate selection of tools that folds down into the most compact package among its competitors because its competitors can’t even fold at all. They’re either no more than a regular pair vice grips with a parasitic knife in one handle (Irwin so embarrassed of it, it’s not even on their website anymore) or they don’t fold at all (also not listed on the official Kershaw website).

At about $200AUD, it’s alright for the price; but since it got discontinued – reran – discontinued again, the supply has been funneled down into the hands of collectors who trade them for 3 times the price, only to put behind glass cases. I’m one of the rare second-hand-hunters actually looking to use them (or maybe people who actually use it love it too much to sell them). Not to mention most of them are in the US which insanely hikes up the shipping.

Then on one fateful day of me idly browsing Ebay on a whim, I found a deal of a lifetime. A Crunch? At MSRP or best offer? In Australia? In NEW CONDITION? From a seller that just signed up and is also selling a bunch of other knives in new condition as well? Yeah it smelt like a scam but with a deal this good and with Ebay and Paypal’s scam protection, I could not pass up on the opportunity. Turns out the seller was some collector’s wife disbanding his knife collection, probably pricing things based off the first result. Needless to say, I was a very happy person when the knife finally arrived.

Sheath Design Inspiration

I’ve never had a Leatherman before and was quite pleasantly surprised by the quality of the included nylon sheath. However, just as I’ve been dreaming about getting a Crunch, I’ve also been dreaming about getting a ZapWizard-style sheath for it (at time of writing, he hasn’t designed one yet and as the Crunch is a niche discontinued product, he probably never will). Just in case someone had already designed something similar, I did some research and only found 2 Leatherman Crunch sheaths on Etsy at time of writing. One is magnetic looks insecure while the other one appears to have unnecessary bulk. Needless to say, I had to design my own so I did.

Personally, I didn’t need my holster to have tool or bit holders. I feel that a multitool ought to be fully self contained so you don’t have to worry about fiddling around a losing accessories. I think the beauty of ZapWizard‘s designs comes from their pragmatism and minimalism; it’s as if the bare tool just sticks onto a belt and I feel that the accessory mounts break that illusion.

My Design

Most Leatherman multitools that ZapWizard designs for have spring-operated metal tabs (as part of the tool) that he uses to lock in the tool which allows for a metal on plastic action that’s resistant to wear. In a similar way, I designed in some nubs which engage with the Crunch’s plier head which sticks out when folded. While I didn’t cut out slits to turn it into a compliant mechanism, the tool snaps in satisfyingly and holds the tool reliably. This might eventually wear out the sheath long-term but I want to test my design out for a while to identify other problems as well before addressing it. I want to eventually finalise a design worth committing to nylon sintering like ZapWizard‘s.

It’s a good thing I did test it out for a bit because I quickly identified an issue.

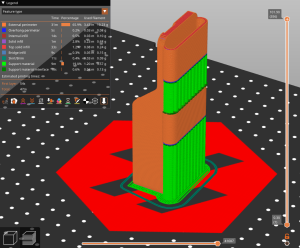

For the Mk1 (left), I just took measurements of the tool and designed channels that run to the end sheath for the Crunch’s protrusions to slide along. However, after using the sheath on an actual belt, I found myself trying to slide the tool in at a diagonal through the center of the long side rather than sliding it in parallelily (adverb of parallel) from the short side. The sides of the big plier hinge channel prevented me from doing that so for the Mk2, I opened the channel up. I also realised that the plier hinge would never interact with the short open end so I also beefed it up and added a gradual slope. Doing this not only made it possible to slide the tool in diagonally, it also made it much easier to line up the tool to slide it in from the short side as well. Also note that I used 3D honeycomb infill instead for the Mk2 of gyroid because it looks better; my printer is tuned poorly so the infill pattern shows through the surface.

One embarrassing (because a good 3D print should not require supports) thing is that for strength, I had to make the belt loops print with supports. This print orientation used minimal supports while also making the loops strongest. This won’t be relevant for laser sintering though.

I’m happy with the Mk2 for now but we’ll see where else I can improve for now. Due to the sharp edges of the Crunch bottom one finger release isn’t comfortable at the moment but I’m not sure if this can be addressed. When pulling the tool out, it pops out suddenly and I want to add some features to slow it down like ZapWizard‘s sheaths.

Future Projects

In terms of other Crunch projects, I want to mod the tools (most of these ideas are from ZapWizard). While I’m incredibly happy with the vice grips (which have seen a lot of use already), the tool selection seems a bit lacking. Currently, the only tool mod that exists for the Crunch is a hammer which just feels wrong; surely whacking the handle sideways into the screw can’t be good for your tool. The serrated blade is fine but most of my knifework is with craft blades; I’m looking at making a exacto blade or scalpel holder. There’s 2 flat heads and a 3D Phillips which are fine but I more often use smaller bits so a 4mm precision bit holder (with built-in bottle opener) would be much more useful to me. The existing built-in bottle opener is surprisingly good (barely dents the cap) but it’s part of the smaller flat head. Also I have no use for a file so maybe I could use a T-shank holder and attach a saw.

Reprint (Update 0)

My original PLA print started bending and finally snapped after a few weeks so I reprinted it in PETG. It locks in just as well, possibly better, and it also is showing no sign of fatigue. I’ll update this post if it breaks again.

Definition of Insanity (Update 1)

It broke 2 more times since. Both in PETG

Model available on Printables here.

Leave a Reply